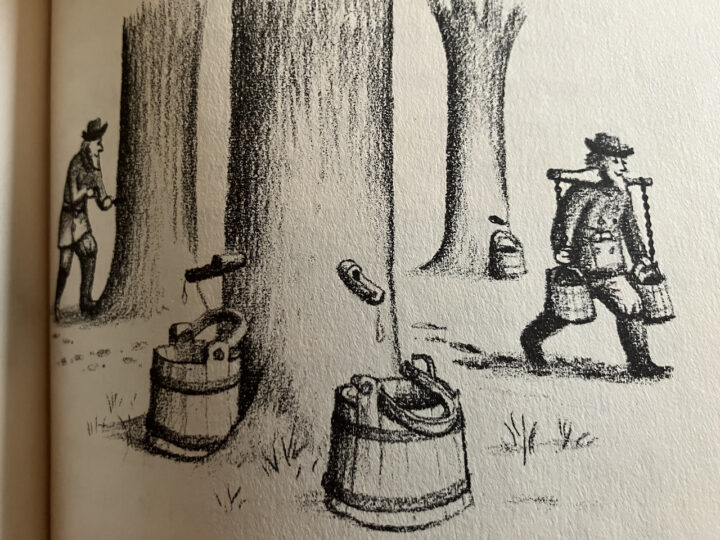

Growing up, I read — and re-read — the Little House series by Laura Ingalls Wilder. I loved the books, the illustrations by Garth Williams — and the stories. Oh, the stories!

After publishing her first book, Little House in the Big Woods, Laura Ingalls Wilder said she received bags of mail from children writing, “Please, tell us another story!”

I loved her stories because she explained how things were made, from building a log cabin and watching Pa create bullets by the firelight to churning butter and making maple syrup.

Living here in New England, I always purchase pure NH maple syrup, but I’ve not seen it made. And I knew about sugar shacks — in fact, you can find sugarhouse tours online — but I hadn’t visited one.

© Dianna Huff, 2025

So, when Rocky and I came upon this sign on our walk one Saturday morning, I didn’t hesitate. “Come on,” I said. “Let’s have an adventure.” I’m glad I did because I spent a wonderful hour learning how maple syrup is made.

A self-taught producer, Jason Steer began making maple syrup in 2012 — in a pot on the stove. A local farmer wanted to hire him to make syrup for the farm’s store, but Steer decided he’d rather do it for himself.

He currently produces 15 gallons of syrup each season; a season can last two to eight weeks, depending on how cold or warm it is. It takes 50 to 60 gallons of sap to make one gallon of syrup, depending on the sugar content.

Larger producers often have thousands of trees from which they harvest sap. The maple syrup industry is located in the upper Midwest and Northeast and includes: Vermont, New York, Maine, Wisconsin, Michigan, Pennsylvania, and New Hampshire. Other states that produce on a smaller scale include Massachusetts, Connecticut, Ohio, and Minnesota.

How the process works

“All winter,” said Pa, “Grandpa has been making wooden buckets and little troughs. He made them of cedar and white ash, for those woods won’t give a bad taste to the maple syrup. He had them all ready for when the first warm weather came and the sap began to move in the trees.” — from Little House in the Big Woods

When I told Steer I knew a little bit about how maple syrup is made and described what I had read in the book, he replied, “That process hasn’t changed much.”

Sap can be collected from any maple, says Steer, including Red Maples, Black Maples, and Sugar Maples, although Sugar Maples give the most yield.

The sugar is stored in a tree’s roots during winter, and as the outdoor temperature begins to rise, the tree begins to feel dehydrated — so the sap rises. The tree needs it to make its buds.

Ideal temperatures for harvesting sap range from the upper 20s F at night to the 30s and 40s F during the day.

“You first have to choose a healthy tree to tap,” says Steer. “It should be at least 12-inches in diameter — which will allow for one tap. With a 36-inch diameter tree, you can do three taps. The tree will seal itself around the hole the tap makes.”

You also have to collect the syrup every day, otherwise it will spoil, like milk. Once Steer collects the sap, he pumps it into a large plastic tank at the back of the sugar shack and then filters it for bugs, bark, dirt, etc.

He runs the sap through a reverse osmosis machine, which removes the excess water; the process helps reduce boiling time. The clean sap flows into the Evaporator, a beautiful stainless steel machine, where it’s vigorously boiled down to remove the water.

As it boils and the water evaporates, the syrup becomes thick and flows into a separate chamber at the front of the Evaporator. Once cool, it’s then bottled.

The Evaporator sits on top of a wood burning stove; Steer constantly feeds the fire and monitors the temperature. As he said, the process isn’t much different from when Grandpa Ingalls collected sap and boiled it over a large caldron in the woods.

If you stand outside the shack, you can see the steam escape from the top windows, which are slanted open. It’s a lovely and peaceful experience on a chilly late winter’s day.

Pure maple syrup is pure

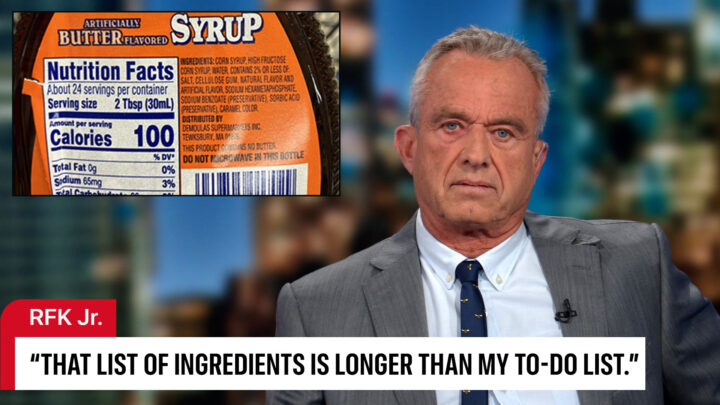

Nothing is added to the syrup — no sugar, additives, coloring, etc. According to the NH Maple Producers Association, “maple syrup is graded or categorized based on the flavor and how much light passes through (translucence). Variations are due to weather, soil, climate, point in season, boiling and more. The quality of all grades is the same.”

© NH Maple Producers Assn.

Pure maple syrup is also quite healthy and good for you! It’s 100% natural and unrefined and is a good source of mineral nutrients.

If you’re not in a maple syrup producing state, you can find it at your grocery store. Look for “pure maple syrup” on the label and the state of origin. I found several at my local grocery.

Store brand “syrup” on the other hand — completely artificial.

Pancakes — yum, yum!

After the tour and interview, I bought a bottle of Mr. Steer’s syrup, came home and immediately made pancakes.

My recipe is pretty standard. I use the one from the Better Homes & Gardens cookbook, early 1990s edition (Made in USA!).

However, I do use the best ingredients I can find, including Caputo “00” Chef’s Flour, fresh raw milk from my local farm, locally raised eggs, and Ultra-Premium Extra Virgin Olive Oil.

Yes, olive oil. One morning, while making pancakes for my son, I realized I didn’t have cooking oil and substituted olive oil. “Mom,” he said, “these are the best pancakes you’ve ever made.” I never looked back.

(Like pure maple syrup, Ultra-Premium EVOO has tremendous health benefits and can be added to just about anything, including baked goods. The difference is amazing, and once you try it, you’ll never go back to the nasty stuff at the grocery store. The EVOO I use is harvested from small, sustainable groves in Greece, Italy, Australia, Chile, etc. and is distributed by Veronica Foods in Oakland, CA. Link below.)

I use lots of organic butter and fry my pancakes on a hot griddle. If your syrup has been in the fridge, put some in a Pyrex cup and warm it up gently using a water bath while making your batter.

The result — oh my gosh. The crispy edges of my pancakes and the taste of the fresh maple syrup had me closing my eyes so that I could savor the flavor and textures. So so good!

After cleaning up, I drove back and bought a second bottle to have on hand. It is the best syrup I’ve had, ever.

Thank you, Jason Steer, for taking the time to talk to me, and to explain how syrup is made! I’m so glad I followed your sign and met you, a few neighbors, and your father.

Get the Keep It Made USA newsletter.

Twice monthly; zero spam.

Links

NH Maple Producers Association

Veronica Foods — The company distributes its Ultra-Premium EVOO under private label and through small stores, including many farm stores. Use their store locator to find one near you.

Also be sure to check out Tom Mueller’s book, Extra Virginity: The Sublime and Scandalous World of Olive Oil. Fabulous read!

Laura Ingalls Wilder Historic Home & Museum — Located in Mansfield, MO. I’ve been there and saw Pa’s fiddle!

HF Coors: Fun Dinnerware Made in the USA — A Keep It Made USA write up

Full Disclosure

I’m not paid nor asked to write about products or the companies or people that make them. All links in this piece are FREE — meaning, they’re not sponsored or paid for.

My mission is to keep manufacturing jobs stateside and this blog is my way of giving back. We like to think a “small” choice, such as purchasing something made in the US or by someone local, won’t make a difference. It does.