In 2015, I made a commitment to buy only American made products whenever the option was available.

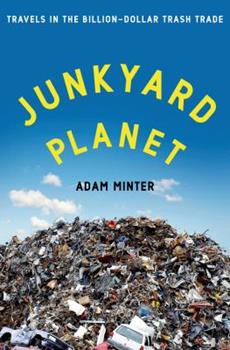

Why did I make this commitment? While doing research for a client, I read a book he recommended, Junkyard Planet: Travels in the Billion Dollar Trash Trade, by Adam Minter. I couldn’t believe what I was reading! Basically, companies offshore the manufacture of cheap goods, which are then imported to the U.S. where they fall apart and get thrown in the trash or recycling bins. Then, a lot of this stuff gets shipped to China and other countries where it’s broken down and remade into more cheap crap.

In addition, I was horrified to read of the awful working conditions to which people are subjected.

I realized there was no way I could work every day with the owners or marketing teams of American manufacturing companies — only to turn around and shop the shelves of Target, Home Depot, etc. without regard for where products are made — and how they’re made.

I’ve never regretted my decision to buy American-made goods. I do it because American manufacturing provides so many benefits, including stable, well-paying jobs in the factory or plant and to the local community at large (think restaurants, dry cleaners, gyms, professional services, landscapers, trades (plumbers, roofers, etc.), and retail, to name a few.

When manufacturing leaves a community, these jobs leave too.

What I’ve learned in since 2015

When you commit to buying “made in America,” two things happen: one, you quickly learn you can’t impulse shop and two, you end up doing a lot of research. Because, let’s face it, if you’re shopping at your typical big box store, your choice of made-in-USA products will be slim.

In the course of doing your research, you learn that companies making products in the U.S. are more than names or logos. You discover where they’re located. You learn their history. You might end up talking with their sales or customer support teams – or even the owners or founders!

(This is how I learned about and met many of the manufacturers I’ve interviewed over the years, such as the founders of Barn Light Electric, Authenticity 50, and Floyd.)

You quickly learn that these companies are made up of real people. People with families, cars and mortgages. Many of these companies are family owned. All have a story to tell.

In addition, you learn just how critical these companies are to the towns, regions, and states in which they’re located.

Fletchers’ Mill

For years I relied on the inexpensive salt and pepper shakers I bought back in college. I would also buy those whole pepper containers with the built-in grinder from the supermarket. After going through a fair number of these, I realized it was time for an upgrade!

So, I set out to find a replacement – made in the U.S., of course.

As you might expect, many cheaper pepper mill models are made in Asia. A few of the more expensive models are made in Europe.

But some are still made in the USA.

I eventually settled on the Glenburn salt and pepper set from Fletchers’ Mill and ordered it online. Here they are – handsome, aren’t they? It’s been a delight using them – they’re incredibly well-made.

Let’s deconstruct this salt and pepper set for a moment.

✔️ The set is made of wood (Fletchers’ uses sustainable forestry practices and recycles all wood waste).

✔️ The salt shaker has a rubber stopper in the bottom and a metal plate on top (which I’m assuming would have been stamped).

✔️ The pepper mill has a metal internal grinding mechanism — which would have been machined to tight tolerances in order to deliver the very smooth grinding. The mill also has a metal screw on the top.

Suffice to say, all of these parts would either need to be made in-house (using machines that quite possibly were made in the U.S.) or brought in from other suppliers.

And then, of course, the product needs to be assembled, Q.C.’d and shipped.

As you can see, even a relatively “simple” product, such as a salt shaker, can involve sophisticated supply chains and processes — all of which require highly skilled workers!

From humble beginnings . . .

In 1971, brothers Wayne and Earl Fletcher had a vision of owning a business, so on a wing and a prayer they mortgaged their homes and took ownership of an antiquated mill that once served as a blacksmith shop.

Located in New Vineyard, Maine, the company now employs 100 people. The company also practices what it calls “forest to table.” Wood for its products comes from sustainably harvested sources; all sawdust and scrap wood is recycled and used in a variety of products, including wood pellets used to heat many New England Homes.

The advantages of buying American

There’s another reason to feel good about buying American: you end up with products of excellent quality and function. Of all the items I’ve purchased over the last six years that have been U.S.-made, only one fell apart and that was a pair of shoes. I promptly emailed the manufacturer, who was appalled and sent me a replacement pair immediately.

The higher quality makes sense: manufacturers here in the U.S. oversee their own production processes.

Another advantage to buying American is that you end up buying less stuff – and your house ends up having a lot less clutter. When one friend visited a few years ago, her jaw dropped. “OMG,” she said, “your house has zero clutter!”

(Well, some of that was due to Marie Kondo, but yes, I only buy stuff I love now.)

Most important, when you buy U.S.-made products, you know your money is supporting the employees who work in the company — and indirectly the people who work in the community where the company is located.

You can imagine the impact to the local economy of New Vineyard, ME (population 757) if Fletchers’ Mill were to go under; everything from the local gas station and lunchtime café to the barber and daycare center would be affected.

But what I love best about buying products made in the U.S. is that I know they’re made by workers protected by OSHA standards. I’m not contributing to poor worker health, unsafe work conditions, or sheer disregard for the environment — all of which is rampant in countries where cheap goods are made.

My vision is to help keep manufacturing jobs in the U.S. and to keep American manufacturing as strong as possible. I do this by helping smaller manufacturers grow through marketing – and by buying American whenever possible.

Get the Keep It Made USA newsletter.

Twice monthly; zero spam.

Full Disclosure

I’m not paid nor asked to write about products or the companies that make them. All links in this piece are FREE — meaning, they’re not sponsored or paid for. I buy products, use them, and if I like them, I tell everyone about them.

I do this because my mission is to keep manufacturing jobs stateside. This mission is my way of giving back. We like to think our “small” choices won’t make a difference. They do.

Betty Lynne

Thanks so much for the mention of Barn Light Electric! We have 120+ team members who are proud to handcraft lighting, home goods, and furniture right here in America each and every day!

Dianna Huff

Hey Betty Lynne! I love your products (have two of them!) and can’t wait until I redo my kitchen and can add some lights from your expanding product line.

Ann Calvert

Dear Dianna,

Thank you!!! We want to buy only products that are made in the U.S.A., and your comments and hard work toward that end are very encouraging.

Have you found a thermal coffee carafe that is truly made in the U.S? Your assistance would be such a huge relief!

Thanks so very much; God bless you!

Dianna Huff

Hi Ann,

Wow! You have officially challenged me. Even the listings that say “Made in USA” are not! Bunn is assembled here but of imported components.

Give me a couple of days. Now I’m interested. There has to be one company in the US making these things. You want the travel type insulated thermos / carafe, correct?

Steve

Hi Dianna, thanks for your article. I’m a carpenter and DIYer and I have to rummage thru yardsales and pawnshops looking for Made in the USA. I wish there was a data base showing all the Made in USA companies so we could find them and purchase their goods. Most people must have realized by now if it’s made in China it breaks after a few uses and you end up buying it again and again with the same results. I found items made in the USA are more expensive but they usually last a lifetime. So until we teach this to young people we will continue to support China while our own country is destroyed. Please continue to get the word out.

Dianna Huff

Hi Steve,

Thank you for the comment and for visiting my website. I often buy vintage Made in USA as well. Found an awesome 1960 bathroom scale this way!

Jeff Kulp

Hello Ms. Huff,

I also am looking for a thermal carafe made in the USA. Have you had any luck finding one? I’ve done searches online & come up empty.

Regards, Jeff Kulp

Dianna Huff

Jeff, I’ve not been able to find a Made in USA carafe. I’ve visited several stores and did extensive research online. The next step I’m considering is viewing companies that produce lines of cookware or kitchenware to see if one has a carafe hidden in the product mix.

Emma

Have you checked out thesnowplow.com (THE SNOWPLOW “THE ORIGINAL SNOW PUSHER”).

All their snow shovels are sourced, manufactured and sold in the U.S.A

Dianna Huff

Emma –Oooh, thank you! I didn’t know of this company. Need to add it to my interview list.

G. Uess

Constructed in America, yes employs AmERICans!!!

Dianna Huff

Absolutely!