Updated: July 29, 2024

My Floyd sofa is now five years old and has held up incredibly well — despite the addition of Rocky in 2022. He loves to jump on it and have a seat. My son sleeps on it when he visits, and during the winter, I like to sprawl on it and watch a movie.

Recently, I went to check out the Floyd website because a colleague had asked for a Made in USA furniture manufacturer. I’ve learned to always confirm these things as companies and their business models do change.

Such is the case with Floyd, I’m sad to say. The company has raised its second round of funding, having secured a Series B $15M in 2022 to expand its “sustainable furniture brand.” It has also increased headcount from 30 employees to 85.

Whenever I see VC money, I always think “uh oh,” because investors mean a huge push for growth and profitability — which translates into moving production to other countries.

So, I wasn’t surprised to see this note buried in the website FAQs:

“Floyd products are designed in Michigan and manufactured by our partners across the United States, China, and Mexico. We have strict quality standards and we strive to employ environmentally and socially responsible sourcing and manufacturing practices. Our production takes place in factories with decades of passionate manufacturing expertise.”

— Where are Floyd products manufactured?

Change and growth are good. I’m happy to see the two founders have expanded business. However, I’m dismayed that its products are now only “designed” in Detroit — similar to how Apple products are “designed” in Cupertino.

For this reason, I can no longer recommend Floyd as a true Made in USA manufacturer.

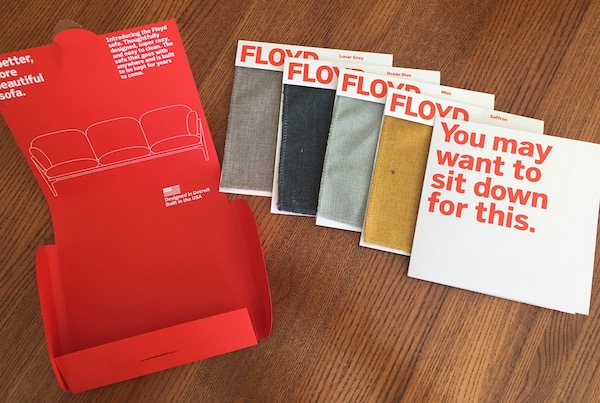

With the infusion of cash, and its growth mindset, the company has lost the wonderful original branding, such as what you see on these sample cards. I still have them — that’s how much I loved their branding!

Now, it’s simply an e-commerce play with all the right sustainability buzzwords and messaging.

As part of its growth, the company is updating its original sofa; Sofa 2.0 will debut in August 2024.

I’m still proud of owning an original Floyd sofa 1.0. As you’ll read in the interview below, it was made / sourced by manufacturers local to Floyd in Detroit. I won’t be updating it with the new modular components made somewhere else.

Lesson: ALWAYS, always, always do your due diligence when searching for Made in USA products and read the fine print, or in this case, the FAQs. If you can’t determine where a product was made, then it most likely wasn’t made here.

I’ve not made any changes to the original 2019 interview.

Interview with Floyd Co-Founder, Kyle Hoff

In business for almost six years, Floyd, Inc. designs, manufactures, and sells home products, including a sofa, bookcase, bed platform, and tables. The company’s design ethos centers around “Furniture made for the home, not the landfill.”

I discovered Floyd through a referral; a friend who knew I love and use products made in the US sent me the link. One look and I was in love. 😍 It was a short courtship; a few weeks later, I ordered the Floyd sofa.

In this interview, Kyle Hoff, CEO of Floyd, talks about the company’s beginnings and how they created a high-quality, modular sofa that arrives to your home in a flat pack – and is assembled in about a half-hour.

DH: When shopping at a brick and mortar store for furniture, you rarely see or learn how the furniture is made. Instead, as a consumer, you focus on colors, fabric, shape, or price. What made you decide to share your engineering / manufacturing process with your audience on the Floyd website – and what feedback do you receive about it?

Kyle Hoff: Traditional furniture is about seasonality; it also tends to be a commodity. And few furniture companies create stories behind their pieces.

We knew from the beginning we wanted to make thoughtfully designed products more accessible and show how the products work, where the materials come from, and our thinking that goes into the design. People like reading our story and learning what goes into creating our products.

DH: Yes, that’s what makes your products different. The one word that kept coming back to me as I built the sofa was “engineered.” Your products are well-thought-out and efficiently designed. And, they’re modular!

KH: We draw our inspiration from the greats of the mid-century movement, many of whom worked in Michigan, including Charles and Ray Eames, and George Nelson. Like them, we put a lot of thought into our products and design them for the way people live.

The sofa fabric, for example, withstands spills, pets, and kids. All our furniture is modular, which means it can be easily broken down and reassembled. You can order the sofa with or without the chaise; if you decide later you want the chaise, you can add it – you attach it with two bolts. If you need to move the chaise from the right to the left side, you can easily do that.

We custom designed and engineered the hex bolts used to attach the backrest and platform to legs and frame so they lay flat under the cushions. Ditto for the easy-to-turn hand knobs. Even the Floyd tool that doubles as a bottle opener was something we thought through.

DH: Yes! Love the Floyd tool. So, do you source your materials from US suppliers?

KH: All of our furniture is designed in-house, then it’s manufactured locally. We work very closely with manufacturers that we know. Our supply chain is regional: Ohio, Pennsylvania, Michigan, Tennessee, North Carolina. For example, the sofa assembly is done by a La-Z-Boy facility in Tennessee.

When it comes to sourcing, we look for the best source of a material while also considering the carbon footprint. The linoleum for the tables, for example, comes from the Netherlands as the company there produces the best material, and they’re eco-friendly.

We use a lot of birch. The US however, doesn’t have an abundant supply of it, so we source the material from Poland. The sofa cushion foam is sourced in the US; the fabric is a mix of US and Asia.

What all this means is that having a regional supply chain allows us to be nimble. We don’t have to order thousands of pieces of something and then have them sit on a boat for eight weeks. All our furniture is made-to-order; when we get feedback from customers about a problem, we can adjust really fast.

DH: What prompted the epiphany about keeping furniture out of landfills?

KH: When I was in college, I bought cheap furniture and then threw it away. When you’re younger and more transient, you tend to use furniture that’s designed to be disposable.

The amount of furniture that ends up in landfills is a real problem, but it wasn’t always this way. Furniture was designed to be passed down or used for decades. Companies today have made it easy to purchase inexpensive items and then throw them away after a few years of use.

Anyway, it was something I became aware of, which led to experimenting with the idea of well-made but modular furniture. I was living in Chicago in an apartment with Craigslist roommates at the time.

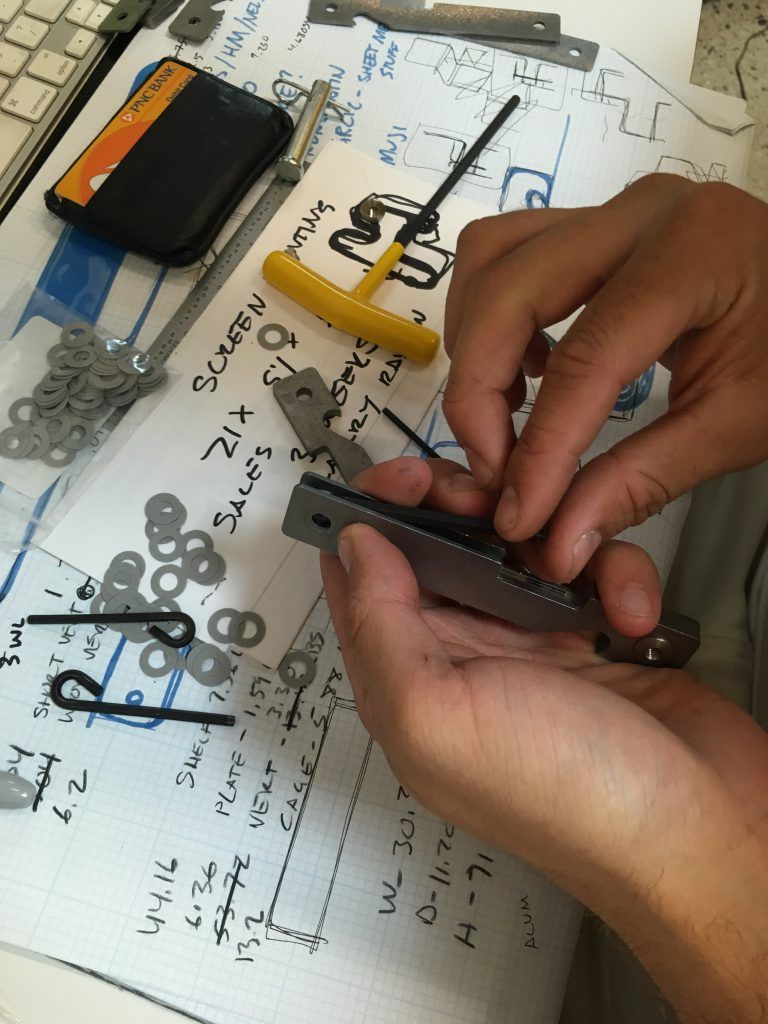

I came up with a drawing for table legs. The legs combined a clamp with clean, modern design. You could then use the legs with your own table material and shape – glass, wood, round, square.

I cold-called twenty manufacturers before I finally found one who would make the legs. Part of the problem was my drawing (laughter).

I moved to Detroit to help my friend Alex O’Dell (who became Floyd’s co-founder) launch a separate business. We launched the table leg product on Kickstarter. We knew our frustration with furniture and wanted to see if it was a pain-point that registered with others.

We set a goal of raising $18K on Kickstarter – the money would be our capital for doing a manufacturing run versus letting the legs gather dust in a closet.

We raised $250,000. It was very exciting but incredibly terrifying, too. We used the money to design the bed frame, sofa, and bookshelf.

DH: Do you work with an agency or do you come up with your messaging yourself? And when you first started, how did you get the word out?

KH: All our messaging is done in-house. We have 30 people, including a design team and a marketing team. All of our products are sold directly to the consumer through our website.

DH: What’s interesting is that you manufacture in Detroit. Are other smaller manufacturers like Floyd based in Detroit? Is manufacturing changing and growing in this area?

KH: There’s lots going on in Detroit and Michigan as a whole, and yes, manufacturing has changed in a lot of ways. We see a great deal of innovation and creativity, not only from the automobile manufacturers, but from unexpected places, such as Motown, and of course, startups. Manufacturing still has a large presence in Detroit – and it’s a great place to visit!

Visit Floyd’s online showroom.